1.Technology to revamp the building process!

Reconfigure a room in just minutes with the new robotics startup from Asmbld. Co-founder, Petr Novikov called this invention “like 3-D printing upside down.” The “Project Dom Indoors” works with tiny robots that are inside cubes created from 5-inch tiles and aluminum studs that make the floor of the room. The cubes then can rise out of the floor and create anything from surfaces like tables to creating an entire wall to separate the room. The tiny robots have the ability to make the cubes into new configurations and transform any room into a conference room or just a lounge. Naturally then they can take their original position in the floor.

Asmbld stated that it would approximately cost $12,000 to have it installed in a 500 square foot room. They would have to re-floor the space and make the floor 5 inches higher than the floor the room currently had. Despite the cost, Asmbld said that it could potentially save the building owner money in the long run. The reconfiguration of the room after it’s installed is essentially no cost.

2. Thermal Bridging

Thermal bridging is a process where heat transmissions through a wall and is passed directly through the building envelope. It can go through masonry, block or stud frame, or internal fascia like drywall.

Nasa has developed a technology called Aerogel, it was made for cryogenic insulation. It’s considered one of the most effective thermal insulation materials! US spin-off Thermablok adapted cryogenic insulation

using a proprietary aerogel in a fibreglass matrix. This is used to insulate studs which can increase overall wall R-value, a measure of thermal resistance, by over 40%.

3. 3D printer maybe the future of construction!

Russian engineer Nikita Chen-yun-tai has a new development as of October of this year. A 3-D printer that can create a 1,000 square foot building of ANY height in one day! Apis Cor printer can print a house layer upon layer with efficiency at high speed!

This machine is shaped like a tower crane with commercial extruder that rotates with two planes and has a printing zone of up to 630 square feet. It prints slopes, walls (horizontal and vertical), and produces absolutely no construction waste while also saving you up to 70% over frame construction!

4. Self-driving crash trucks at roadside work zones

In Coopersburg, PA an equipment company has announced a self-driving truck back in August of this year, though it’s too soon to be used by the highway construction just yet. These driverless trucks were created as a sort of “crash truck” and actively blocks traffic from hitting exposed construction workers. The hope is to decrease the constant danger of moving traffic next to their site.

The truck has a device that receives the signals it needs to move and is then directed to do the job. This is drawing tons of interest from transportation companies around the country! Not only are these trucks a guaranteed safety net but they can potentially save you money, time, and labor pains from needing fewer drivers on your crew.

5. Parking lot ‘drinks’ 1,000 gallons of water in 1 minute

Thanks to a video demonstration permeable concrete has become the new hot topic in the construction world! This concrete can ‘drink’ you under the table! The video shows the product Topmix Permeable that can absorb more than 1,000 gallons of water in just one minute!

Every day untreated sewage is dumped into local waterways and onto the beaches. This creates a significant source of pollution for our rivers and reservoirs. Topmix was created to help reduce the overwhelming amount of stormwater that routinely floods the U.S. wastewater systems.

How does it work? Topmix Permeable is put over a layer of gravel that allows water to either permeate the ground below or have it diverted elsewhere through a series of pipes. The empty spaces in this new kind of concrete that allows the water to flow through is limited and can’t really be used in heavily traveled highways as it’s more rigorous of an application. Tests are being performed about the raising questions about the possible damage that can be cause from the water freezing or snow.

6. Photovoltaic glazing

Your building could generate it’s own electricity by integrating photovoltaic glazing! Essentially this will turn the whole building into a giant solar panel. Many companies provide transparent photovoltaic glass as a structural material when building, companies like Polysolar. This amazing glass technology can also be used when forming windows, facades and roofs!

Photovoltaic glass could help you save money on energy bills and even help earning feed-in tariff revenues. The cost is marginally over traditional glass since the construction and framework costs still have to be factored in, while the costs for cladding and shading systems are replaced.

7. Modular construction

Modular construction is a process where a building is constructed away from the construction site using the same materials and being designed to the same standards they would at the site. This process was started to limit the environmental disruption that happens with changing seasons. This essentially will make it possible to do construction projects all year round! Modular construction has strong sustainability benefits like creating less waste and having fewer vehicle movements.

Image Courtesy of Raconteur

Not only does this process make the worry of weather on construction sites obsolete but it saves you enormous amounts of time! Chinese developer, Broad Sustainable Building has already completed a project using this method. The 57 storey skyscraper was completed in just 19 working days!

8.Cloud collaboration

What if you could share your data remotely from your construction site instantly? Well now you can with Basestone! This system is used as a review tool for engineers and architects digitizing the review process for your construction projects. The cloud based collaboration tool focuses on the installation of everything on site.

From light fittings and steel beams to doors and windows the system is used what are called “snags”, those are issues that happen during construction on PDFs. The user can then mark and add notes through the basestone software! Estimates show that the cost of savings could be around 60% compared to taking the paper route of construction.

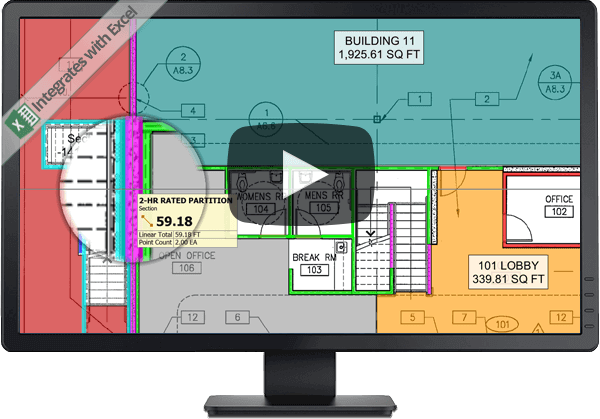

9. PlanSwift 10.0

In 2015 PlanSwift, the number one takeoff and estimating software, released a new version of their software, Pla nSwift 10.0.

nSwift 10.0.

PlanSwift 10.0 was designed specifically to help save you time and money. Instead of having to do click after click after click to takeoff an area, this tool does it all with one single click on your screen.

To learn more about this amazing tool see our Single-Click Feature article on our blog!